Cruising: the secrets of the Cruising Mainsail

Portrait of a mainsail for cruising sailboat

All our sails are designed and manufactured in France, in All Purpose sail lofts.

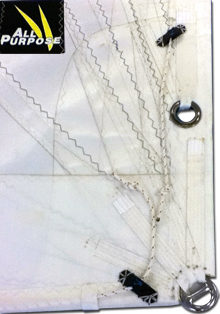

Leech line purchase system

Leech lines led back via the luff are equipped with a 3, 4 or 5 strand purchase system, depending on the size of the sail, as there is more friction.

The purchase system is hidden in a pocket which closes with velcro or a zip, depending on your wishes.

Tack

The tack features a cunningham secured with webbing. It is easier to increase luff tension using the cunningham rather than the halyard.

The cleats are sewn at the tack to make adjustments easier and safer while sailing.

Outboard reef point

A stainless steel ring is sewn in with webbing at the outboard reef point.

The ring is embedded to ensure that it stays in place. A double hand-stitch provides extra security for increased loads while taking the reef.

Head

Our mainsails are equipped with solid headboards (plate effect) in order to spread the loads.

You can see on the photo that there is a small block through which the leech line is safely led back to the tack.

Leech line system

For leading the leech line back to the luff, we use a system which doubles the leech line at each reef point.

The leech line is of a fixed length at each reef point. When a reef is taken, only the corresponding leech line is under tension so that it acts only on the part of the leech being used.

.jpg)

Clew

For this clew on Pen Duick, we used webbing with a breaking strain of 6 tonnes.

The displacement of this boat and the loads generated by it oblige us to over-specify the finishing.